The Personnel Dimension

Takes into account the location of the personnel with regards to the safety of being notified by a signaling device. This would include restrictions due to ear and eye protection.

The Special Conditions Dimension

These are the unique factors in the surrounding environment that could affect personnel’s hearing or seeing an alarm, or the life of the alarm’s operation.

The Spatial Dimension

Determining the actual effective coverage volume for audible and visual signaling devices.

Designing with 3D-Coverage Avoids Incorrect System Sizing

3D-Coverage Ensures Guidelines are Implemented More Efficiently

Standards such as EN 54-23 require that the ambient conditions within a space covered by a signal are taken into account. They specify the output level of signaling devices but do not account for their technical performance surrounding signal transmission – leading to a risk of incorrect sizing. Planning with the aid of 3D-Coverage eliminates this risk. It provides a precise indication of the number of signaling devices required and allows the system to be specified in an efficient, cost-effective manner.3D-Coverage is More Reliable Than Marketing Data

Performance data supplied on technical data sheets often results in naïve assumptions about the actual performance of a product. When combined with inadequate consideration of factors such as the ambient noise levels, the danger of insufficient signaling perception is increased. 3D-Coverage takes these factors into account and ensures that audible and visual signals can be heard and seen.Device Performance Within

a Defined Space is Immediately Apparent

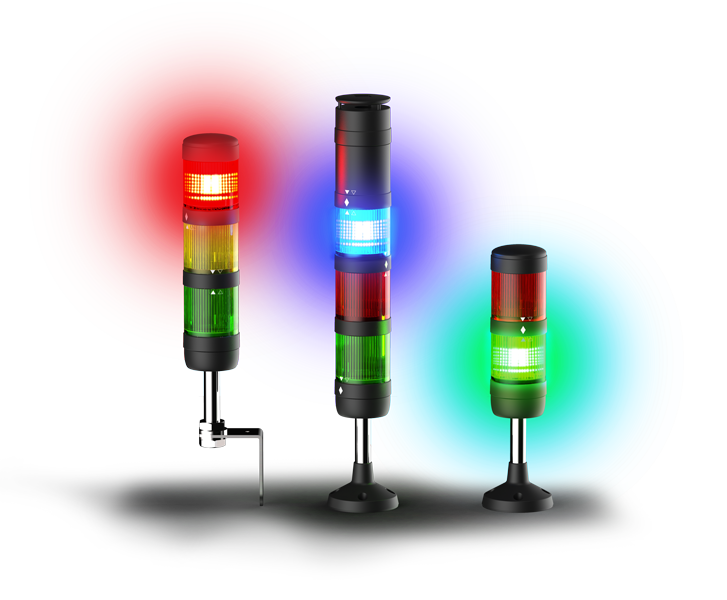

Understanding Signaling Coverage - The effective coverage area for each device varies with requirements for alarm, warning, or indication.

Indication Requirements

Used to inform machinery operators of certain functioning conditions, or nearby personnel of

the status of a situation which is generally low priority. The illumination requirement is typically

limited to a localized area.

- Status of a machine, process, or test procedure.

- Lack of raw material / material supply is nearing depletion.

- Quality defect, pass/fail information.

- Process has ended, standby position.

- Notification and display of errors.

Warning Requirements

Used to alert personnel of nearby danger or a process or condition is in need of attention.

These are medium priority situations.

- Moving vehicle or machine – get out of the way.

- Dangerous situation – proceed with caution, safe guards have been removed.

- Status is critical, ready for handling – action required.

- Attention is necessary.

- Process out of tolerance – corrective action needed.

- Health hazard – stay clear.

- Caution – a status change is being executed.

Alarm Requirements

Used when immediate evacuation is needed for emergency situations.

These are high priority situations.

- Evacuate immediately – fire or gas leak detected.

- Acute health risk – toxic substances identified.

- Process is abnormal or out of control – immediate action needed.

- Maximum tolerance exceeded – immediate attention required.

.svg)