Choosing the Correct Cooling Unit | How to Size your Cooling Unit | Important Info

When are cooling units necessary?

- If cooling cannot be accomplished by the outside air.

- If the temperature required inside the electrical cabinet should be equal to or lower than the ambient temperature.

- If the ambient air is strongly contaminated with oil or conductive dusts.

- When higher ingress protection is required (Type rating).

Important for the use of Cooling Units:

- Ensure a good supply of air intake and outtake from the external circuit of the cooling unit, so that thermal energy can be transferred to the surroundings.

- The lowest temperature inside the enclosure may not necessarily be the best. The 95 °F (35 °C) preset by Pfannenberg represents a good compromise between service life and the accumulation of condensation.

How do I know if a cooling unit is the right product for my application?

- If the ambient temperature is greater than the target internal temperature of the enclosure, active cooling is required.

- If a NEMA Type 12 to 4x rating is required - closed loop systems can maintain the NEMA Type rating of the cabinet.

- If the ambient air is strongly contaminated with oil or conductive dusts.

![]()

![]()

Time Saving

Tool-free patented mounting design allows for quick and efficient assembly that considerably reduces installation costs.

Large Fin Spacing

Large condenser fin spacing allow for longer maintenance periods, even without an additional Nano coating.

Simple Installation

World largest possible cut-out compatibility providing unit replacement with the least possible installation work thanks to intelligent mounting systems.

Condensate Evaporate System

Cooling mode starts automatically upon exceeding the required cabinet temperature. The condensate evaporator only activates when necessary for maximum energy savings.

{PC = PD - PR }

- PC [ Watt ]:

Refrigeration capacity of a cooling unit. - PD [ Watt ]:

Dissipation loss: Thermal power generated inside a cabinet by the dissipation loss of components. - PR [ Watt ]:

Radiant heat gain/loss: Heat transfer through the skin of the enclosure (insulation factor not included).

{PR = C x A x ∆T }

- C [ W/m2

°C ]:

Coefficient of heat transmission. - A [ m2 ]:

Surface area of electronics cabinet. - ∆T[ °C ]:

Difference in temperature between the ambient air and the air inside the electronics cabinet

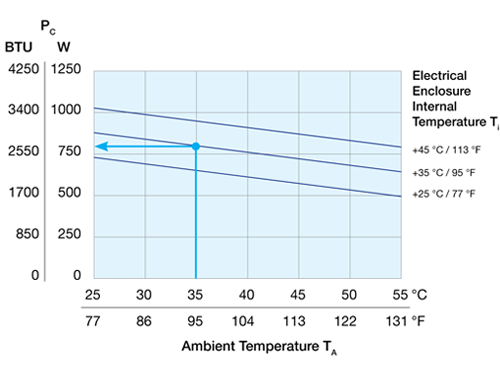

Utilizing performance curves to properly size cooling units

Pfannenberg utilizes the DIN standard 35/35 °C when rating our units. Many other companies use 50/50 °C, which provides a higher, non-usable value. Customers should use their own application temperatures to determine the proper cooling capacity of the system.

Important Information When Utilizing Cooling Units:

- The refrigeration capacity should exceed the dissipation loss from the installed components by approximately 10%.

- The enclosure should be sealed to prevent the inflow of ambient air.

- Use the door contact switch to impede operation with open doors and consequent excessive accumulation of condensation.

- Use cooling units with maximum clearance between air inflow and air outflow to prevent poor circulation.

- Make sure that the air inflow and air outflow in the external circuit is not hindered, preventing proper heat exchanging at the condenser.

- When using top-mounted cooling units, make sure that components with their own fans do not expel the air directly into the cooling units cool air outflow.

- Make sure unit is level.

- Setting the temperature to the lowest setting is not the optimal solution due to the condensation issues. The value we have preset on the cooling unit is a sound compromise between cooling the inside of the enclosure and the accumulation of condensation.

DTS 3000 Series

Pfannenberg’s DTS 3000 Series Cooling Units are driven to meet the demands of our North American NEMA market. These units meet the needs on indoor NEMA Type 12 applications, NEMA Type 3R/4 outdoor applications and NEMA Type 4/4x stainless steel for washdown applications.- Low ambient availability

- Greater range/options in cooling performance

- 115V options

DTT 6000 & DTI 600 Series

- Multi-controller availability

- Energy Saving Mode

- External Displays

- Phase protection

.svg)